Truck Rack Process Optimization: A Case Study in Refinery Performance

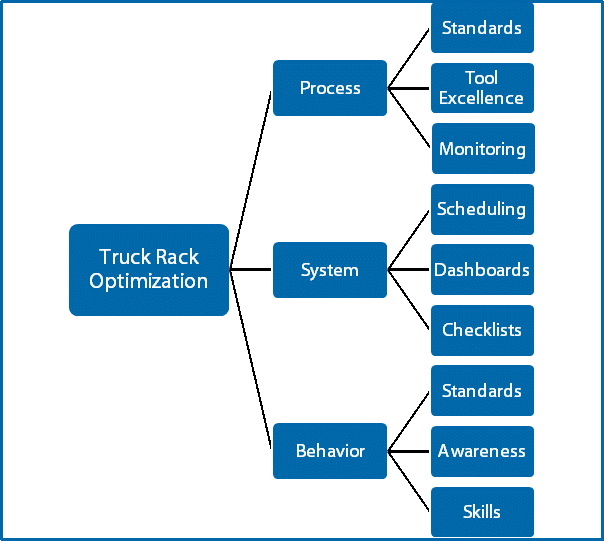

Performance consulting, by definition, deals with the integrity and effectiveness of processes. At Trindent Consulting we know that process effectiveness is impossible to achieve without also addressing two important aspects of every organization: The system, which measures and guides the process, and the behaviour of process participants, which is a direct response to the system.

This is true with the simplest of the processes in small companies and becomes even more important with the increased complexity of medium to large organizations. Oil refineries fit the category of a “complex organization” and have been an area where Trindent Consulting has consistently brought significant value, working with various processes and components, saving our clients millions of dollars without requiring any capital expenditure.

Refining Refineries

Truck Rack operation is a good case study to illustrate the importance of an inclusive approach to process management. It may be considered one of the less complex processes in a typical refinery, but it provides ample opportunity for improvement if the right approach is followed.

Refineries produce many types of products, including various types of gasoline, such as 83 ON and 91 ON. The Truck Rack uses these as ingredients in its recipes to produce gasoline types supplied to the end user. The recipes are well known, the math behind them is straightforward, and measurement equipment is in place to ensure accurate performance. However, Trindent in its work with quality giveaway reduction has repeatedly been able to help refineries achieve significant savings by reducing octane give-away and optimizing the blending process – including the theoretically simple Truck Rack process.

Secret Ingredient

This is achieved by critically evaluating existing components of the process, system, and behaviour; and then addressing any areas of divergence from industry best practices. Combined with proprietary benchmarking and a robust effort to develop solutions uniquely tailored for every client, the approach yields a significantly enhanced competitive advantage. A unique benefit of using Trindent’s approach is that no capital expenditure is required in achieving lower octane give-away numbers, which then translates directly into significant refinery margin improvement.

Another added benefit for refineries is that the improved accuracy in blending and quality control allows them to stay away from failed recipes, which arguably have even larger impact on a refinery by opening it to the risks associated with poor product quality, re-blend opportunity costs and dissatisfied customers.

Hidden Opportunities

Regardless of how straightforward a process may seem, there is always ample hidden opportunity for improvement without capital expenditures. All that’s required is a methodical and systematic approach to addressing all the components. Trindent Consulting specializes in conduct assessments to uncover opportunities to improve refineries’ operations to best-in-class performance

English

English